● Focus on high-quality strategy, efficient driven

● 0-150mm double grooves at one time

●“Made with wisdom”is more.

| Features | |

● Advanced grooving technology, 0-150mm double-groover with double grooving capacity. ● The minimum blind area of alloy knife is 8mm, better coverage in processing. ● Front auxiliary pressurized device following up ,changes with the grooving distance to realize the nearest pressing, which greatly improves the grooving quality. |

| Functional Effect | |

|

High rigid and high precise frame The steel plate frame is processed by a large gantry center with high precision.The frame is processed by automactic welding equipment,and the welding seam is uniform.This ensures the high rigidity of the entire frame. |

|

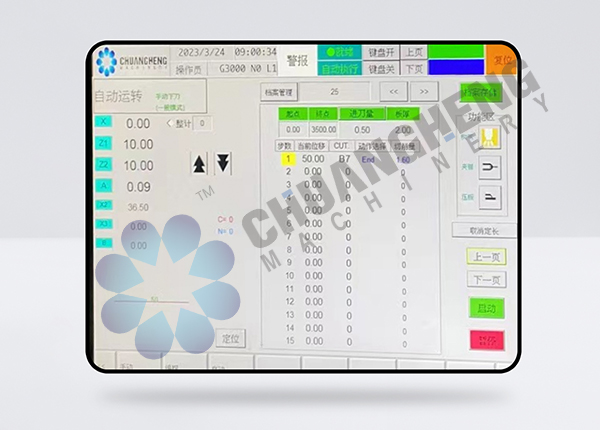

| CHUANGHENG CNC Control System CHUANGHENG CNC CHG66 System ● 15 inch CNC touch display ● Quick input size; ● Bending effect map display; ● Background editing function; ● The machine in operation, can be uninterrupted grooving, no lag, stop the knife; ● Disposable box planing technology; ● Composition function; ● Automatic button size function; ● Back knife function; ● Jump function; ● Sudden power failure boot processing memory; ● Optional industrial cloud function; ● Fixed-point slotting function; |

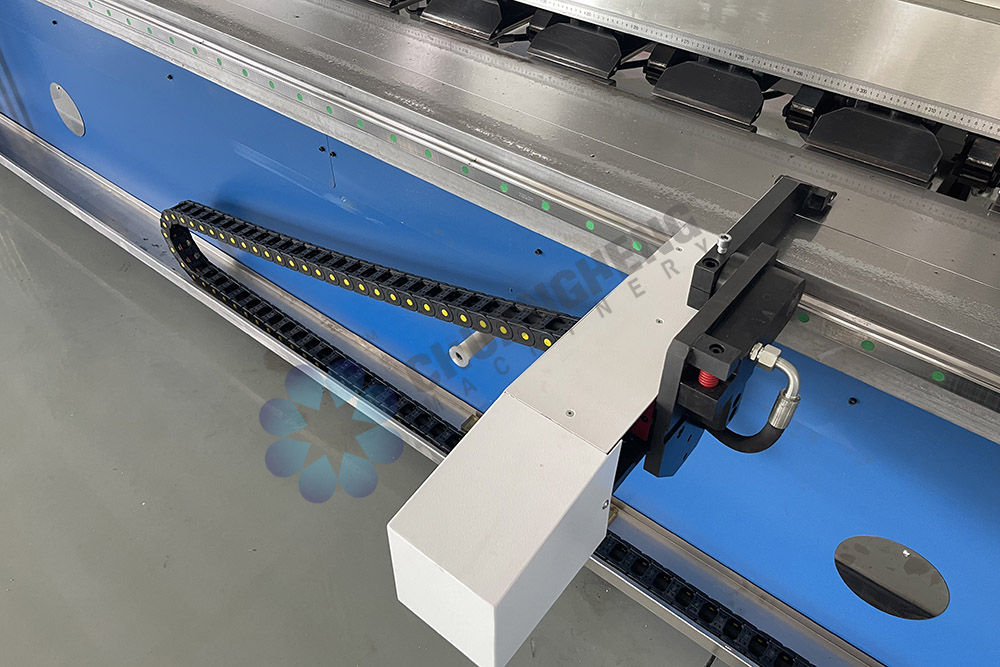

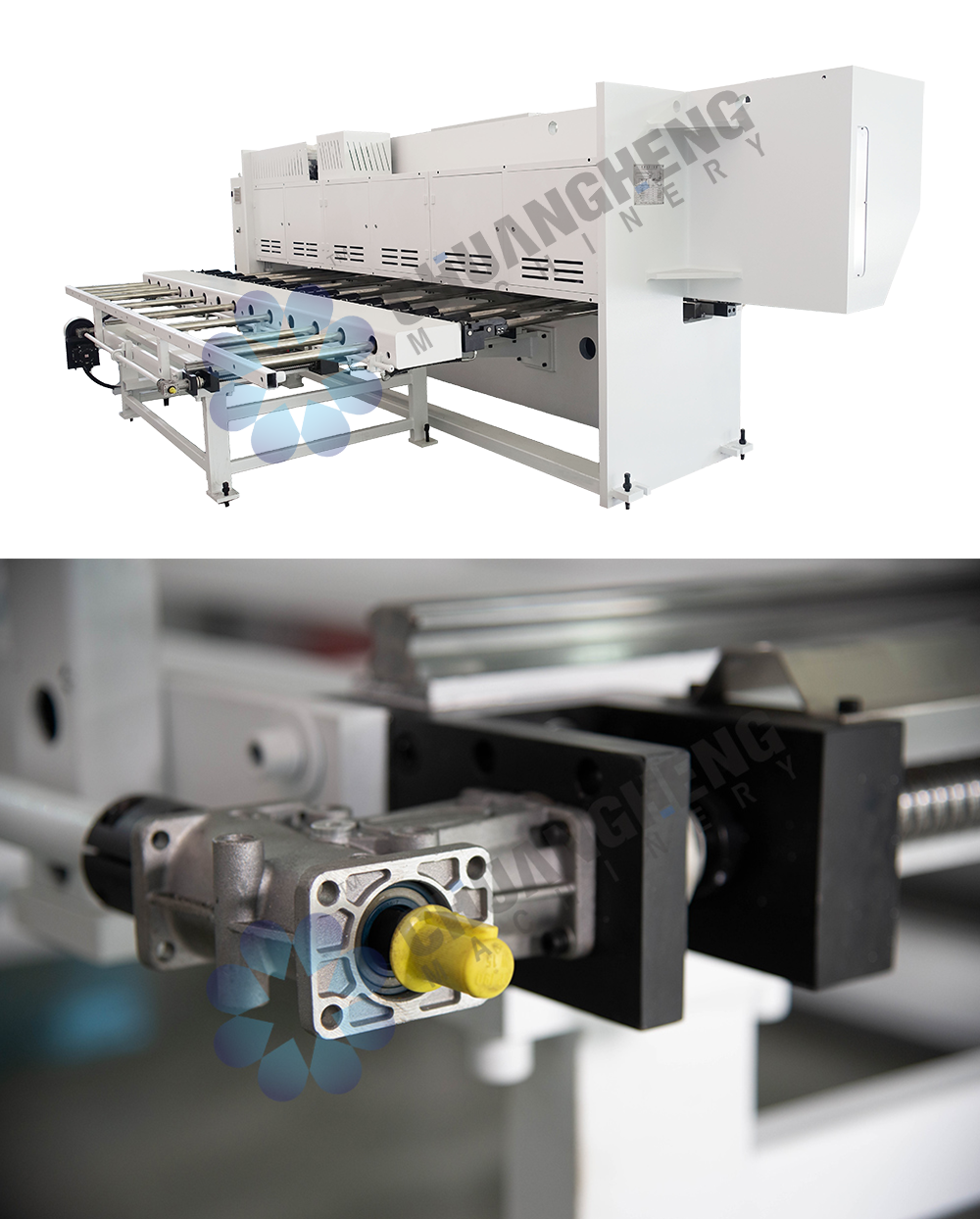

High Efficiency Cutter The tool carriage with 8-12 cutters.0-150mm double grooves at one time.Cutting from right,high speed return after cutting travel. |

|

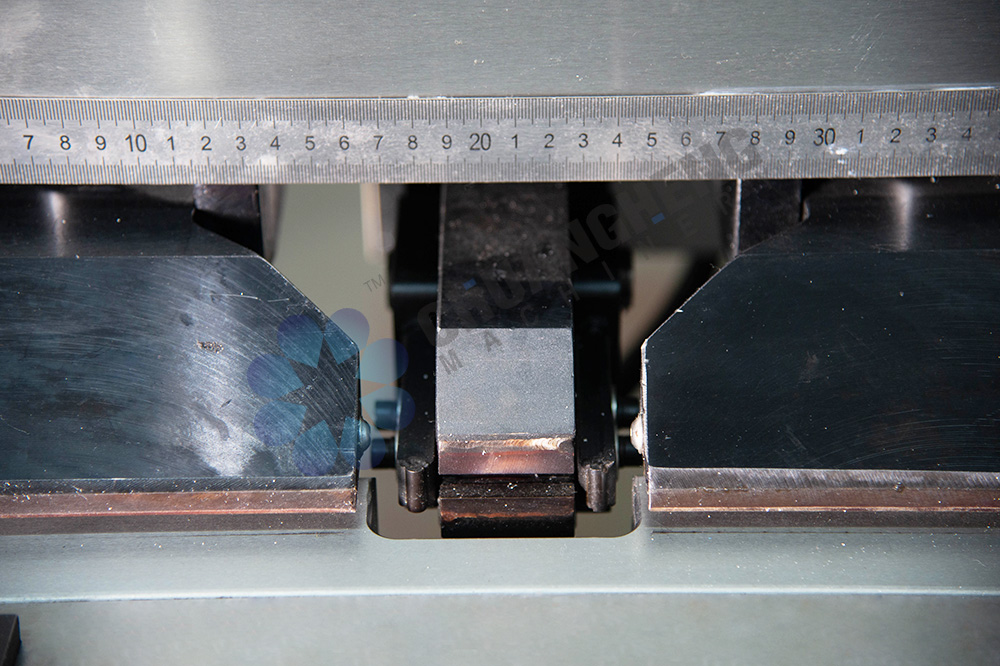

| Adaptive Worktable 42CrMo material worktable, after forging, tempering, quenching, greatly improve the service life. Overall workbench (slotting distance 150mm) can be fine-tuned for fatigue. The deformation can be adjusted and controlled to ensure the machining accuracy of long-term use. |

Front Auxiliary Moving Pressurized device Controlled by CNC system,make the synchronous movement with tool holder, to ensure the groove processing in precision, more intelligent and convenient. |

|

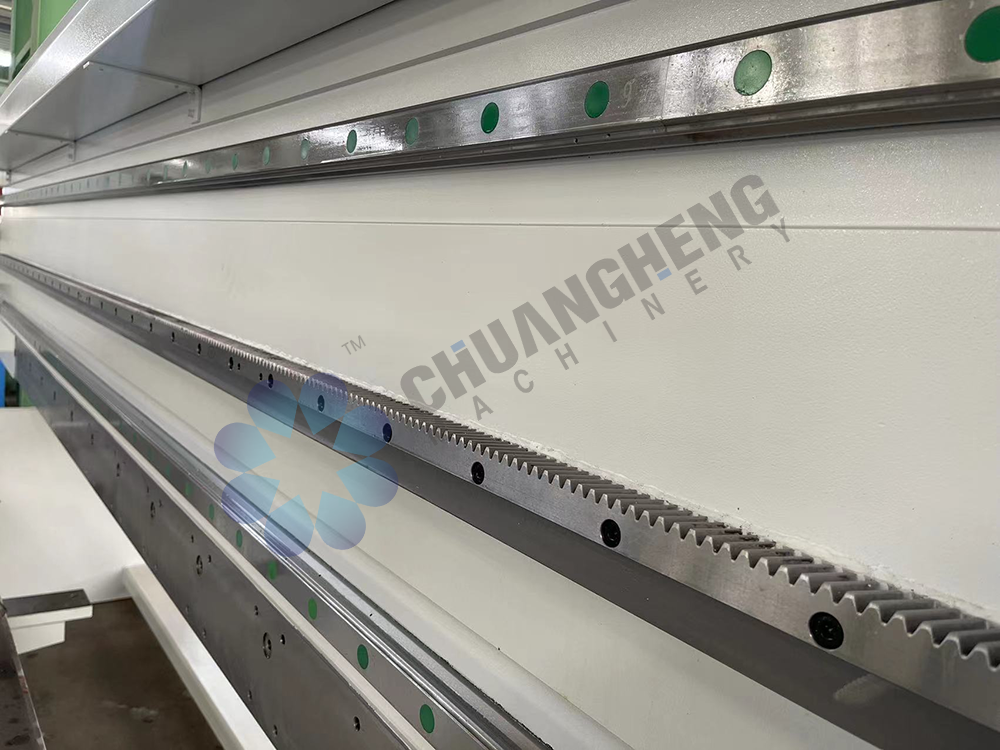

| High Precision Rail Rack Adopt high precision guide rail rack, with high speed servo motor, in order to achieve the effect of stable high speed movement. |

Hydraulic Sheet Clamp The pressure is strong and the pressing material is firm and stable. |

|

| Tool Rest Cooling Device Intelligent cooling,when cutting, protect tools efficiently,extent usage time.Select different cooling way depend different cutting material. 1.drip 2.blower 3.spray. |

Positioning Device After Feeding Driven by servo motor. Compact design synchronous drive shaft. |

|

| Accurate Back Support Device High synchronization of the rear tube position shaft drive, can be with high load clamping plate operation. |

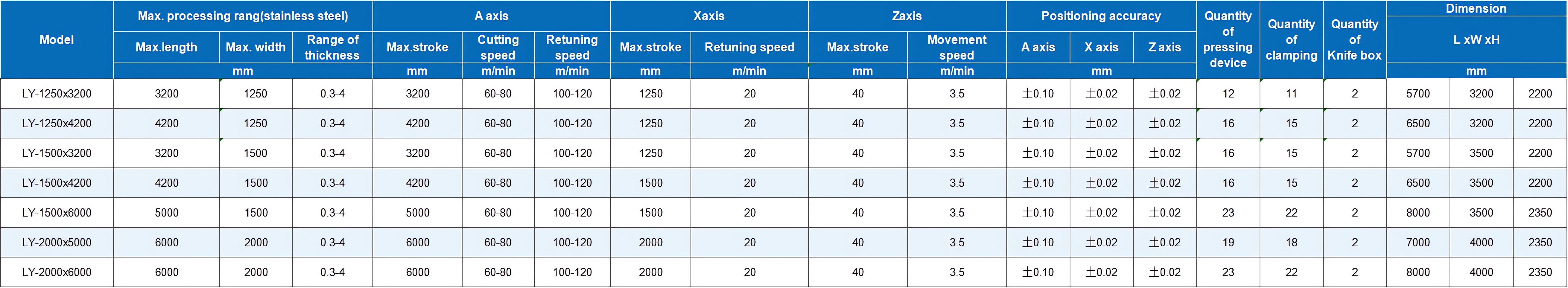

TECHNICAL SPECIFICATIONS

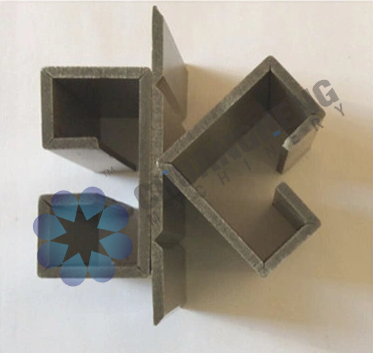

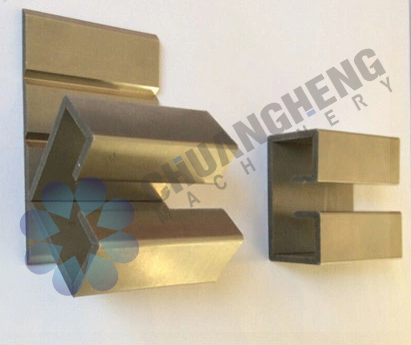

| Profiles | |

|

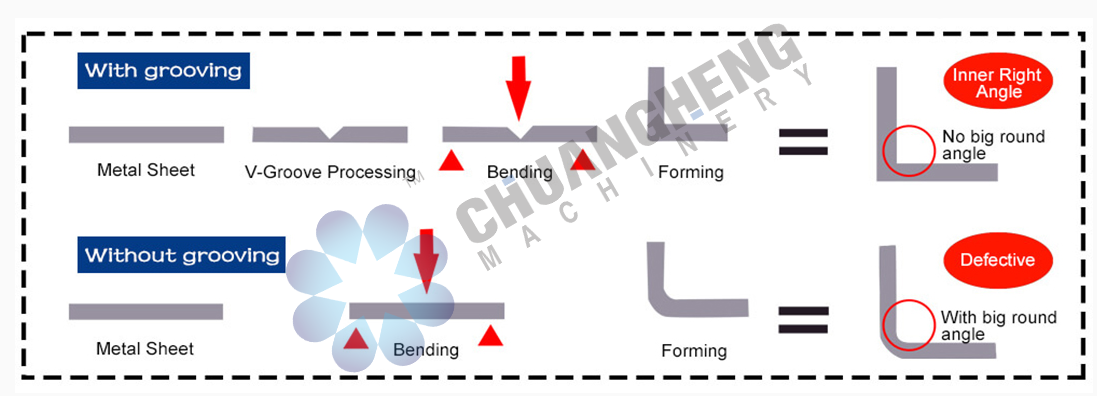

| Application of cnc V grooving machine | |

With the development of the economy,places like hotels restaurants、shopping malls、banks、airports have a growing demand for the bend forming of metal decorative materials in middle and high-grade decoration,such as: ● The bending radius of the workpiece should be small ● The bending angle of the workpiece bending with stainless steel titanium plate or other coloredmetal plates cannot have great color changes. ● No obvious color difference. ● The curved section of the workpiece is more complicated. ● lt can reflect the unique style of the designer. |