● Full welded steel frame,stress relieved by vibration process.

● Equipped with specialized closed loop servo cnc system.

● High speed high accuracy backgauge.

● Hydraulic clamping system with independent hydraulic clamping device.

| Features | |

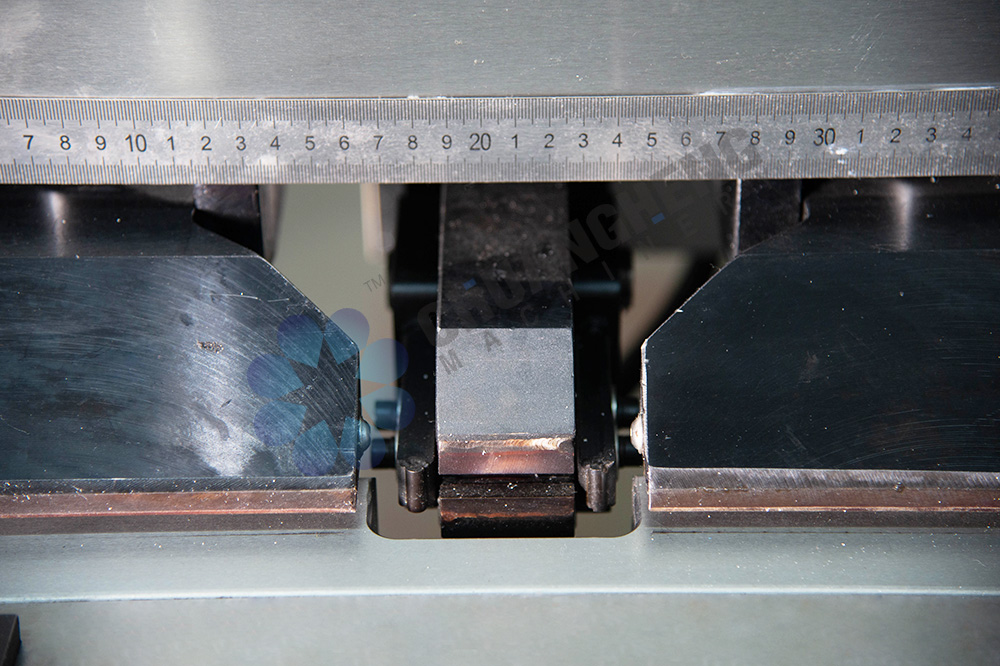

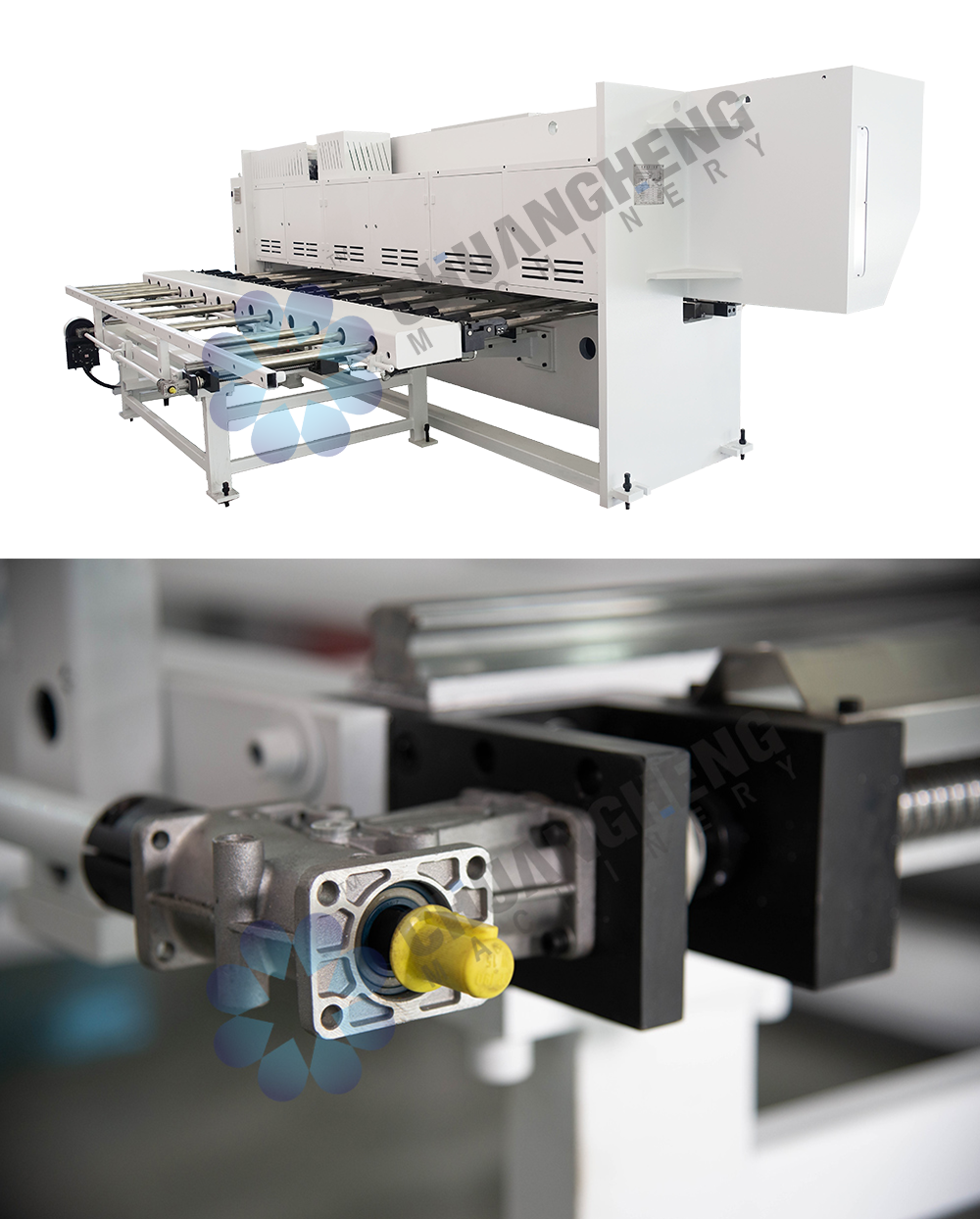

● All welded steel frame,stress relieved by quenching, with high strength and good stability. ● Changeable integral forging working table,through the heat treatment and exact grinding process to ensure high precision,good stability and high wear resistance.Match up the worktable’s adjustable mechanism,ensure the parallelism between the working table and the tool rest's linear guide within 0.02mm. ● Adopts the working ways of double knife holder (six alloy knives or eight white steel knives),the grooving efficiency is high. ● The position of grooving adopts CNC positioning of servo, synchronous transmission by ball screw, positioning accuracy is high,parallelism is good. ● Rear positioning platform connected with stainless steel,reduces the deviation caused by the sheet mental’s deformation. ● Hydraulic pressurized device and independent hydraulic clamping,guarantee the pressurized fastening and stable accuracy. ● High efficiency chip blowing device and cooling system to avoid workpiece damage and improve the blade’s working life. ● Automatic lubrication system,reduce the mechanical friction. |

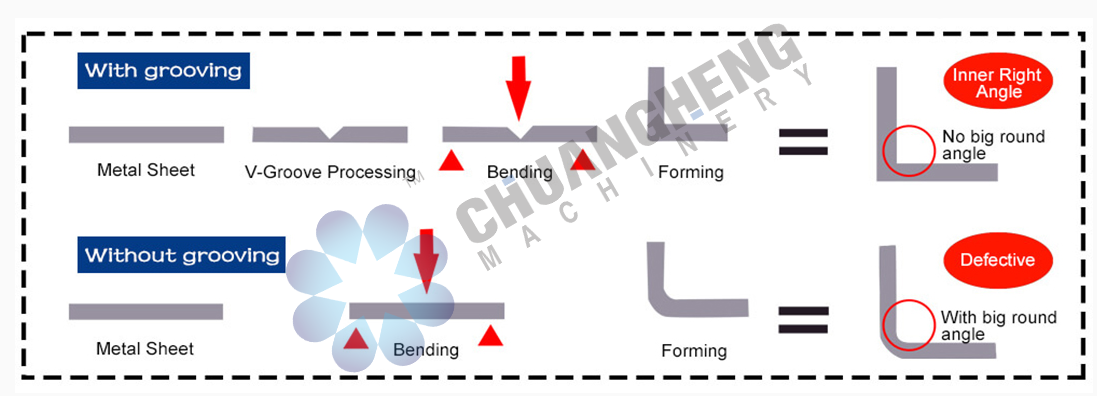

| Functional Effect | |

|

High rigid and high precise frame The steel plate frame is processed by a large gantry center with high precision.The frame is processed by automactic welding equipment,and the welding seam is uniform.This ensures the high rigidity of the entire frame. |

|

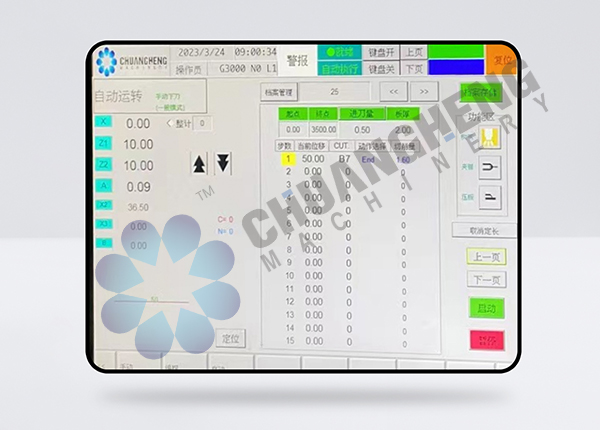

| CHUANGHENG CNC Control System CHUANGHENG CNC CHG66 System ● 15 inch CNC touch display ● Quick input size; ● Bending effect map display; ● Background editing function; ● The machine in operation, can be uninterrupted grooving, no lag, stop the knife; ● Disposable box planing technology; ● Composition function; ● Automatic button size function; ● Back knife function; ● Jump function; ● Sudden power failure boot processing memory; ● Optional industrial cloud function; ● Fixed-point slotting function; |

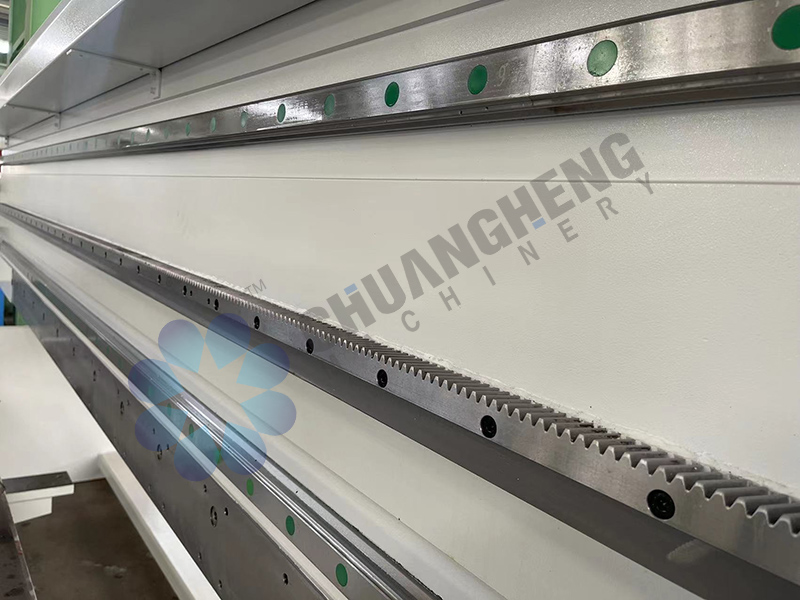

High Precision Rail Rack Adopt high precision guide rail rack, with high speed servo motor, in order to achieve the effect of stable high speed movement. |

|

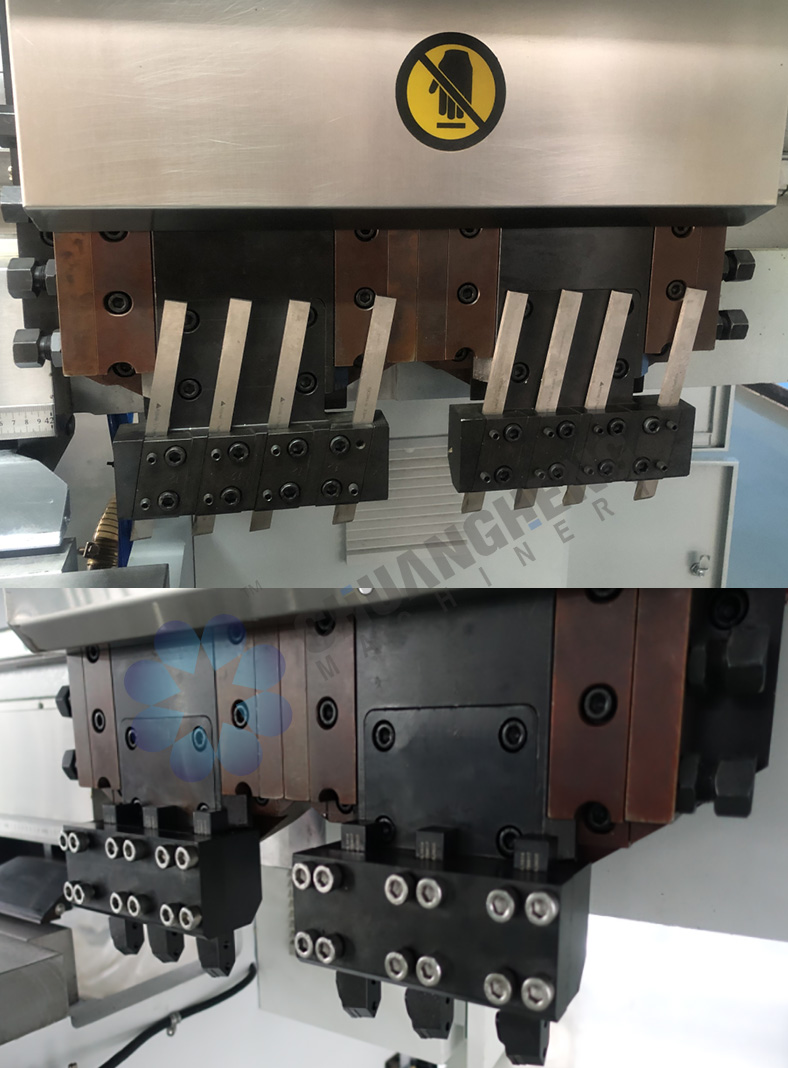

| High Efficiency Cutter The tool carriage with 6-8 cutters.Cutting from right,high speed return after cutting travel. |

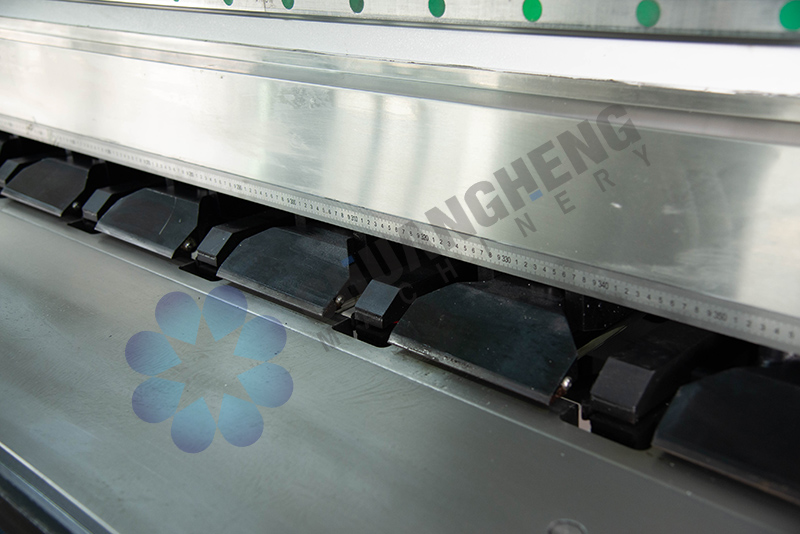

Hydraulic Sheet Clamp The pressure is strong and the pressing material is firm and stable. |

|

| Tool Rest Cooling Device Intelligent cooling,when cutting, protect tools efficiently,extent usage time.Select different cooling way depend different cutting material. 1.drip 2.blower 3.spray. |

Positioning Device After Feeding Driven by servo motor. Compact design synchronous drive shaft. |

|

| Accurate Back Support Device High synchronization of the rear tube position shaft drive, can be with high load clamping plate operation. |

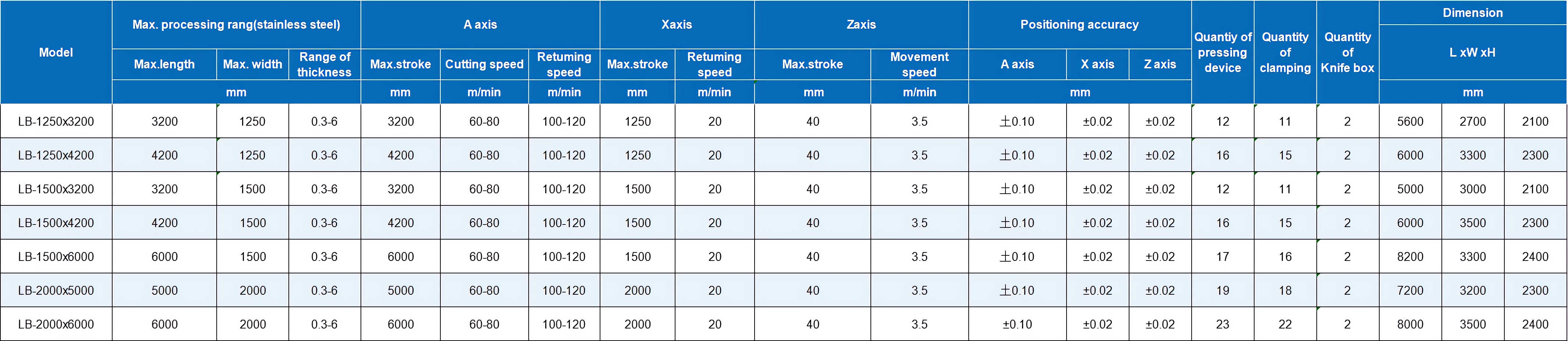

TECHNICAL SPECIFICATIONS

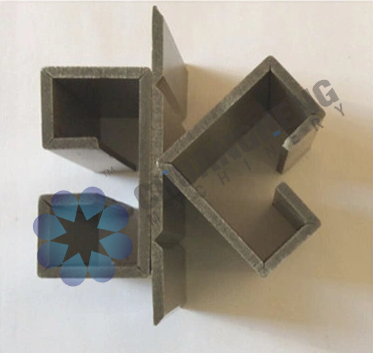

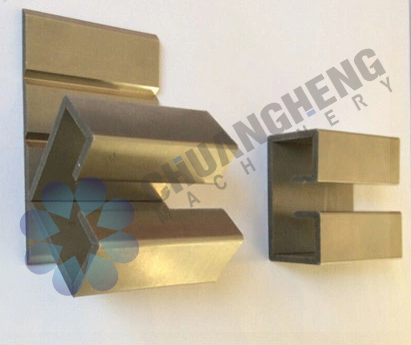

| Profiles | |

|

| Application of cnc V grooving machine | |

With the development of the economy,places like hotels restaurants、shopping malls、banks、airports have a growing demand for the bend forming of metal decorative materials in middle and high-grade decoration,such as: ● The bending radius of the workpiece should be small ● The bending angle of the workpiece bending with stainless steel titanium plate or other coloredmetal plates cannot have great color changes. ● No obvious color difference. ● The curved section of the workpiece is more complicated. ● lt can reflect the unique style of the designer. |