● Accurate backgauge positioning up to 0.01mm

● E21S NC Controller with sequence repeat function

● Quick blade clearance adjustment with manual handle shank

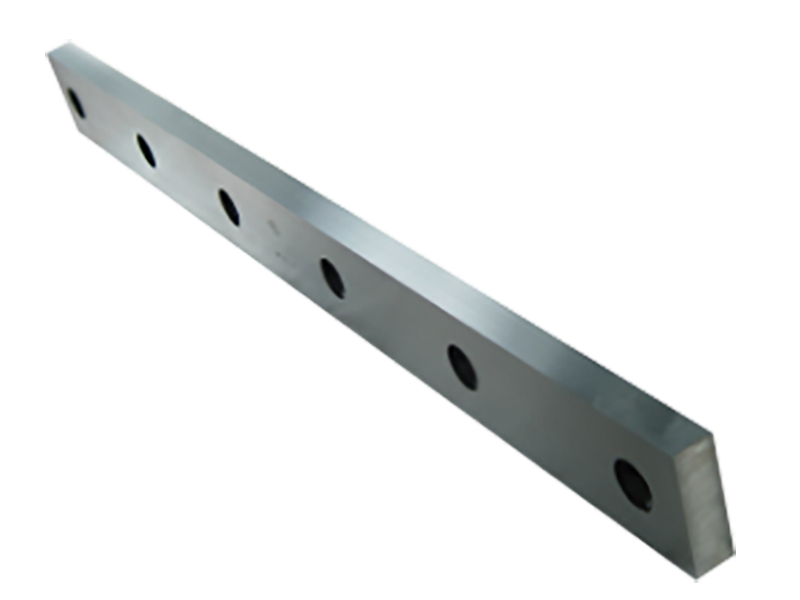

● High quality blades for cutting mild steel, aluminium, stainless steel

| Machine Description | |

1.CHUANGHENG Hydraulic Guillotine shearing machines are characterized by high accuracy and cut quality in al conditions and on any material. 2.The solid frame of the machine and the double plate, that supports the work bench, ensure absolute stability with performance and reliability. 3.The quality of guilotine shear is certied by hydraulic,electical and mechanica components with tigh range. The machines performance excelent n the standard equipment, can beupgraded with diferent components and accessories that are characterized by flawless performances even in extreme working. 4.The options of CNC control panel allows an easier useof the machine optimizing the manufacturing process. |

| Features | |

1. Steel welded structure with stress-free. 2. Three guide trolleys enable accurate movement and fine shearing results. 3. Hydraulically driven blade holder, retracted by cylinder accumulator. 4. Adjustable rake angel to minimize deformation of sheared plate. 5. Back gauge travel can be manually adjusted and knob fined, digital displayed. 6. Swing away back gauge function for cutting longer sheets. 7. Indicator-based adjustment of blades clearance is easy, convenient and swift. 8. 4 cutting edges blad. 9. Full or shorter stroke of blade holder is adjustable. 10. NC controller as standard configuration or CNC controller as optional. |

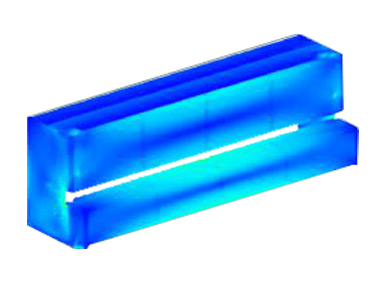

FEA & Stress Analysis Stress Analysis & Finite Element Analysis The CAE software SOLIDWORKS analyzes the linear staticconstruction, stress, and deformation for press break and lasercutting machine frames. So FEA makes sense for complicatedstructures, highly complex loading, transient modeling, and acombination of the above. |  |

| ESTUN E21S Control ● High-definition hydraulic display ● Control common motors and frequency converters ● X-axis intelligent positioning ● Multi-step programming, 40 programs ● Each program 25 steps ● Built-in time relay function ● One-button function switching ● Unilateral positioning function ● A key backup and restore of parameters ● Chinese and English ● Metric system |

Front Tables Roller ball is installed on the arm with ruler can reduce theabrasion and feeder the machine easily and accurately. |

|

| High Quality Blade Rectangular blade, four cutting edges can be used, long service life, the whole length of the knife edge is provided with safety protection grid. |

Hydraulic Hold-down Pads The lower end of the press cylinder is made of non-metal material, which has certain elasticity and large friction coefficient. When cutting the sheet, the press pad can be in closecontact with the material plate to provide sufficient friction toeffectively prevent the plate from being shaken during the process. |

|

| Hydraulic Guillotine Shears Back Gauge System One of the most important factor for bending capacity is the design of back gauge and stability. Quality cutting is possible with perfect product, stabilty and precision back gauge. The high speed ballscrew back gauge system movement is also supported with linear guides, which helps the back gauge achieve long life, greater sensitivity and strengthens against any collisions. |

Optional Equipment

● E200PS CNC Controller

● Front Feeding Table

● Back Photoelectric Protection

● Oil Cooler

● Back Photoelectric Protection

● Backgauge with phenumatic support

E200PS CNC Controller |

Back Photoelectric Protection | Backgauge With Phenumatic Support |

Front Feeding Table Feeding the metal sheet automatically controlled by CNC controller with high precision and efficiency. | ||

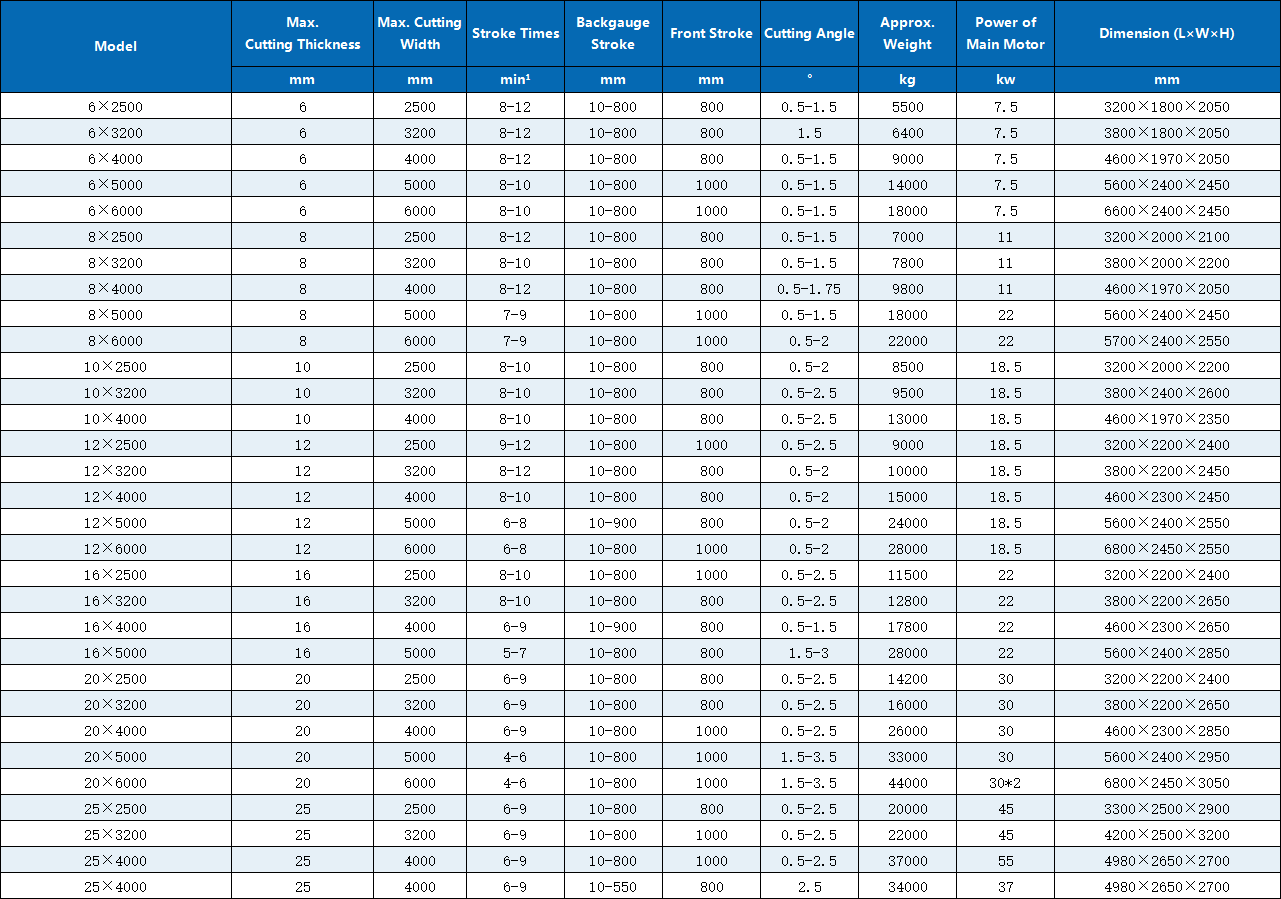

TECHNICAL SPECIFICATIONS