● Humanized high-speed, efficient electric servo bending machine

● High speed and precision, bending small and medium parts of the best choice

● No oil, low energy consumption, less maintenance, more stable and reliable machine

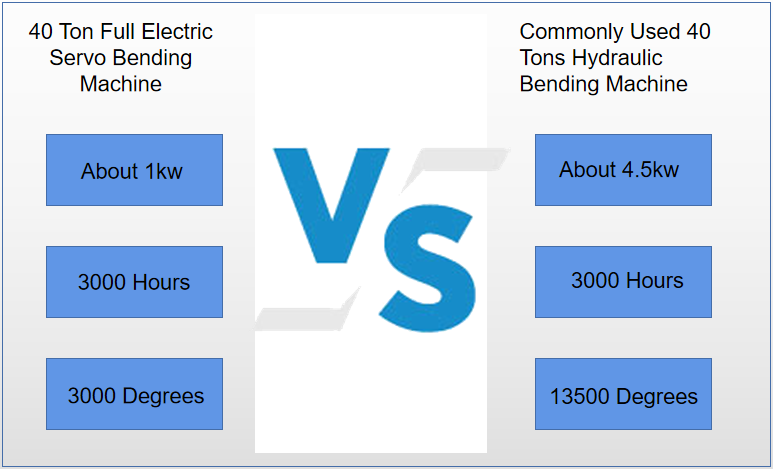

● Compared with the electro-hydraulic machine, the overall energy saving is more than 30%, and the use cost is lower

● Compared with the electro-hydraulic machine, the comprehensive efficiency is increased by more than 40% (under specified working conditions)

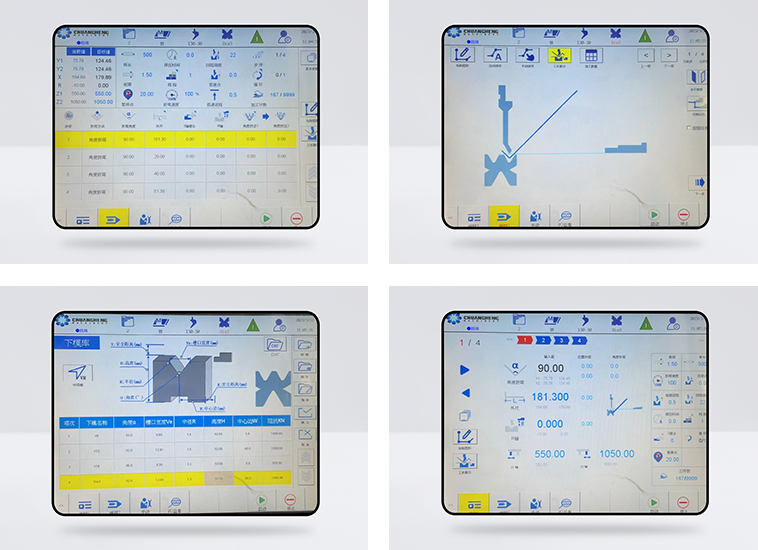

Reliable Performance The CNC system EP adopts a high-end CNC systemevelopment platform and advanced special algorithmsor sheet metal bending and motion control. | |

High-end Design High-end modeling design: CNC systemadopts high-end industrial modeling andluxurious Panel design, 15-inch large-screenLCD touch display, the interface display isclear at a glanceDirect programming function: The systemalso has direct programming function, Forsimple bending, it is most convenient to usethe direct programming function. It is onlynecessary to simply input several parameterssuch as the back file and angle of eachprocess to perform the bending process. | |

Simple and Clear Operation Interface | |

Energy Saving and Environmental Protection CNC system EP is mainly used in all-electric servo CNC bending machine, especially powersaving and green environmental protection.Special power saving: The difference between the power consumption of the all-electric servobending machine and the electro-hydraulic servo bending machine is like the difference betweenthe inverter air conditioner and the ordinary air conditioner. 0.5kW, so special power saving.Green and environmental protection: no need to use and replace hydraulic oil, which ends thepollution of waste hydraulic oil to the environment.

|

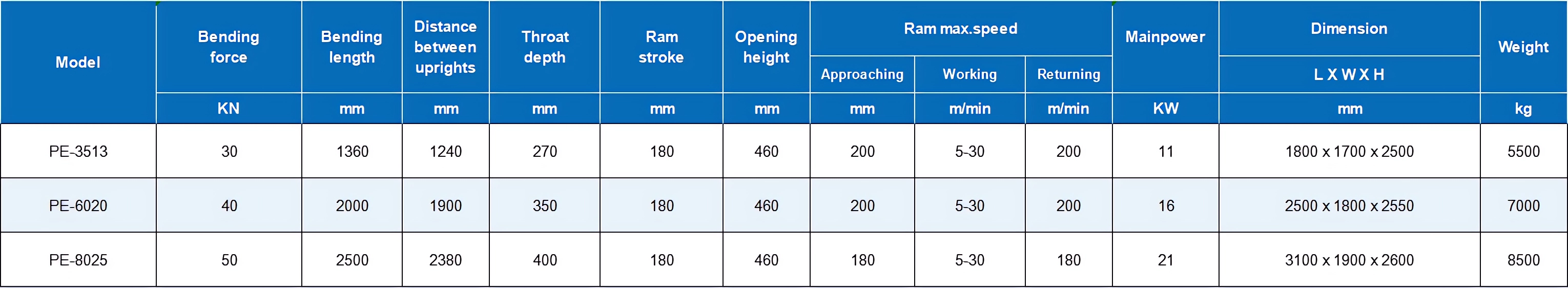

TECHNICAL SPECIFICATIONS