● Designing and Manufacturing are based on reliability, durability and precision.

● Machines are easy to use and are built to be ready to serve for many years.

● Quality and service support is accepted as principle.

| Standard Features | Optional Features |

• Y1,Y2, X ,R+V CNC 4+1 Axes • 250 mm Stroke, 550 mm Throat Depth • DA53T CNC Control Unit • +OO3 accuracy SERVO motorized back gauge X=600 mm • Quick clamp Promecam punch tool holder • Sliding front sheet support arms •CHUANGHENG special narrow bottom table (European type) with motorised crowning compensation • Fargo optic linear scales • Standard 1 set of punch tools and die tools • LED illumination on RAM | • Wide bottom table for Multi Vee dies • Anti-deflection crowning with original Wila wedges • AKAS or DSP front laser safety systems • Additional back gauge fingers • Front laser safety |

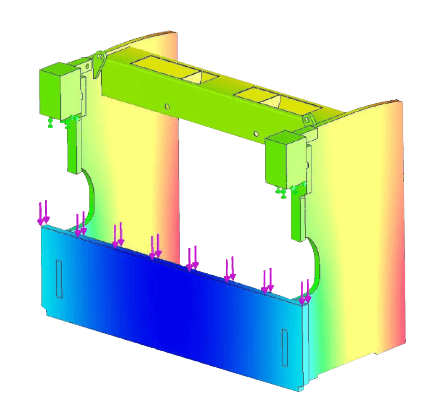

FEA & Stress Analysis Stress Analysis & Finite ElementAnalysis The CAE software SOLIDWORKS used as the method to analyze thelinear static construction, stress and deformation for press break frames. So for complicated structures,highly complex loading's, transient modelling and combination of the above FEA makes sense. |  |

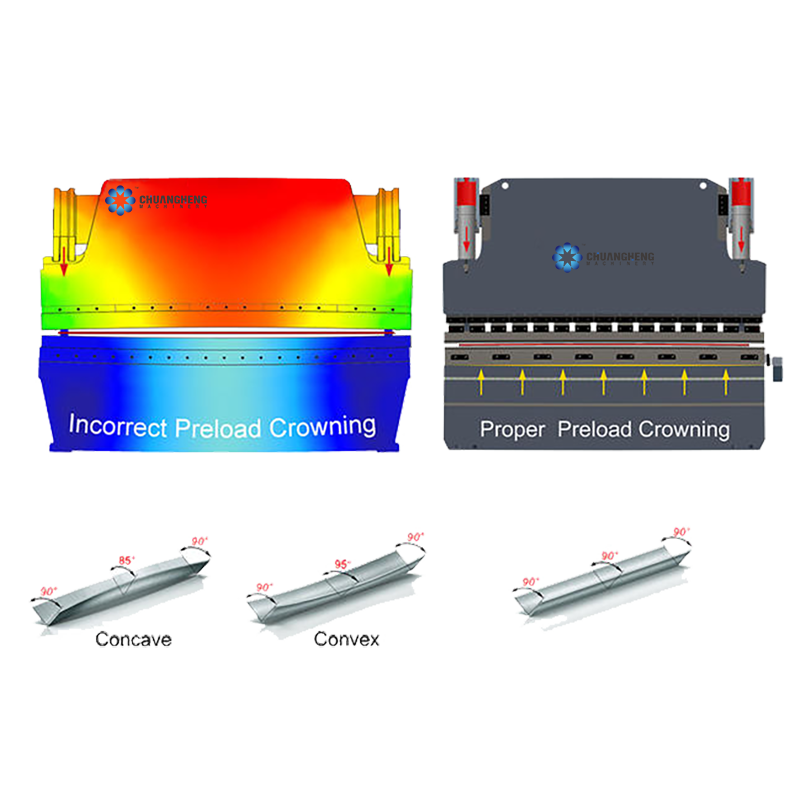

| STANDARD EQUIPMENT Crowning System The crowning system on the CHUANGHENG press brake enables to offset the possible deformations automatically while bending. And the bending angle is constant along theentire workpiece. |

Numerical control system DELEM DA-53T Control

● "Hot-key” touch navigation ● 10.1" high resolution colour TFT ● Up to 4 axes (Y1, Y2 + 2 aux. axes) ● Tool / material / product library ● Servo and frequency inverter control ● Advanced Y-axis control algorithms for closed-loop as well as open-loop valves. ● TandemLink (option) ● USB memory stick interfacing ● Profile-T offline software |  |

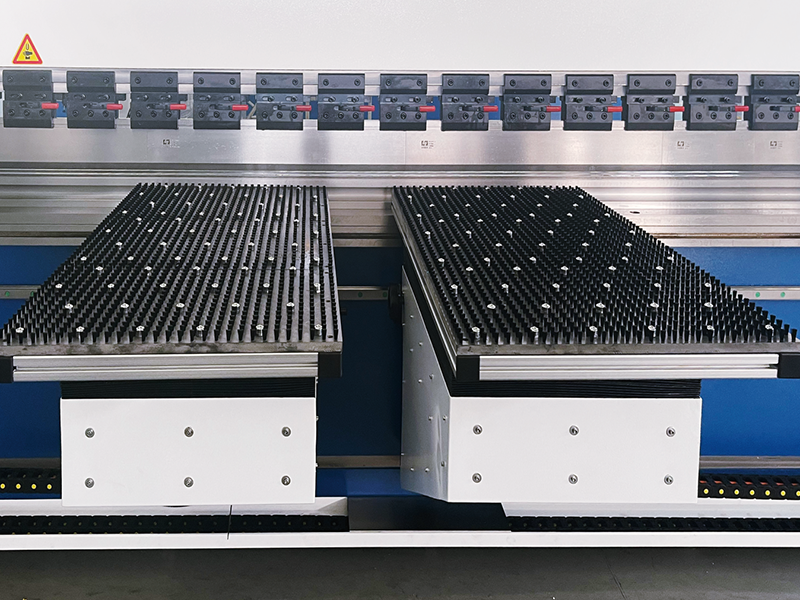

| Fast Clamp The fast clamp could ensure the safe and fast punch changing, with strictquality requirements and procurement standards of raw materials, which keeps the punchfrom falling out. |

Lower die 4V structure The lower die adopts 4V- "T" type fast clamping mode, which can realize quick replacement |

|

| Front Carrier The movable front supporting device can dock at any position to assist your bending work. |

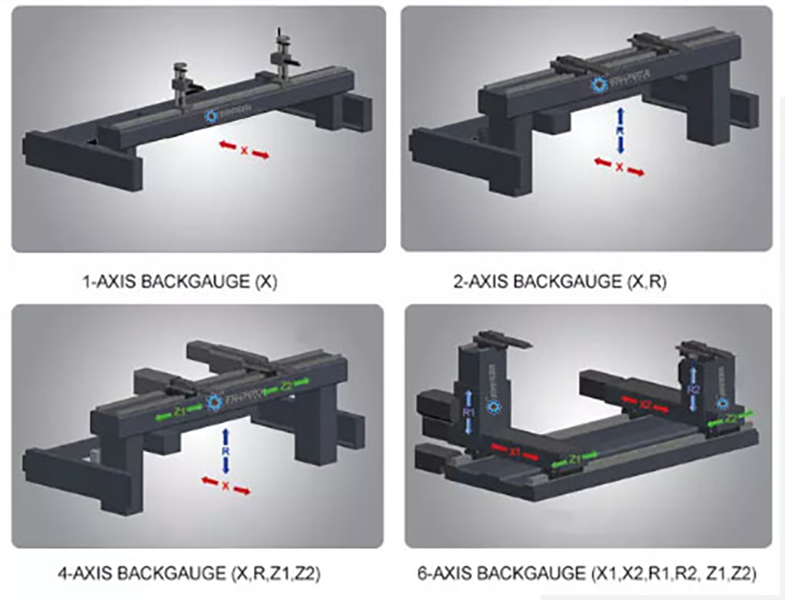

CHUANGHENG BGA-2 BackGauge Sheet Metal Press Brake 2-Axis CNCBackGauge with X, R-Axis ● Hiwin Ball screws and linear guide on X, R-axis ● Axis X speed 600 mm/s. ● Manual Z1, Z2-axis with HIWIN linear guide ● Mechanical accuracy t 0.01 mm. ● Fingers with double stop and micrometric adjustment |

|

Optional

Italy DSP Laser Protection DSP® laser protection will be necessary if you have a high requirement for the safety. Advantage: ● Laser protection, Multi beam Receiver ● Pretective areas, Front, center and rear. ● The safety level is CAT.4 and SIL3 ● Detection Case protection degree: IP 65 ● Laser classification: class 1 M ● Response time: 5 ms ● Change Speed Point : 5mm + Stopping Space ● The maximum protective distance is up to 15M ● LED indicators show various states |  |

WILA Hydraulic Clamping System WILA has focused on the R&D of the hydraulic clamping systems andsupporting tools of press brake machine for many years, and its quality andservice are trustworthy. |

|

Sheet Follower The CHUANGHENG press brake with sheet follower for bending long and thin sheetslt places on the front of the press brake at the height of the bending line. |

|

Robotic Arm The use of robotic arms on the CHUANGHENG press brake machine will be moreproductive and more efficient, lt is another powerful driver in embracingautomation technology. |

|

CNC Backgauge Up to 6-axis controlling CNC backqauge quarantees the flexible bending as customersrequirements. High accuracy with precision ball screws and linear guide. |

|

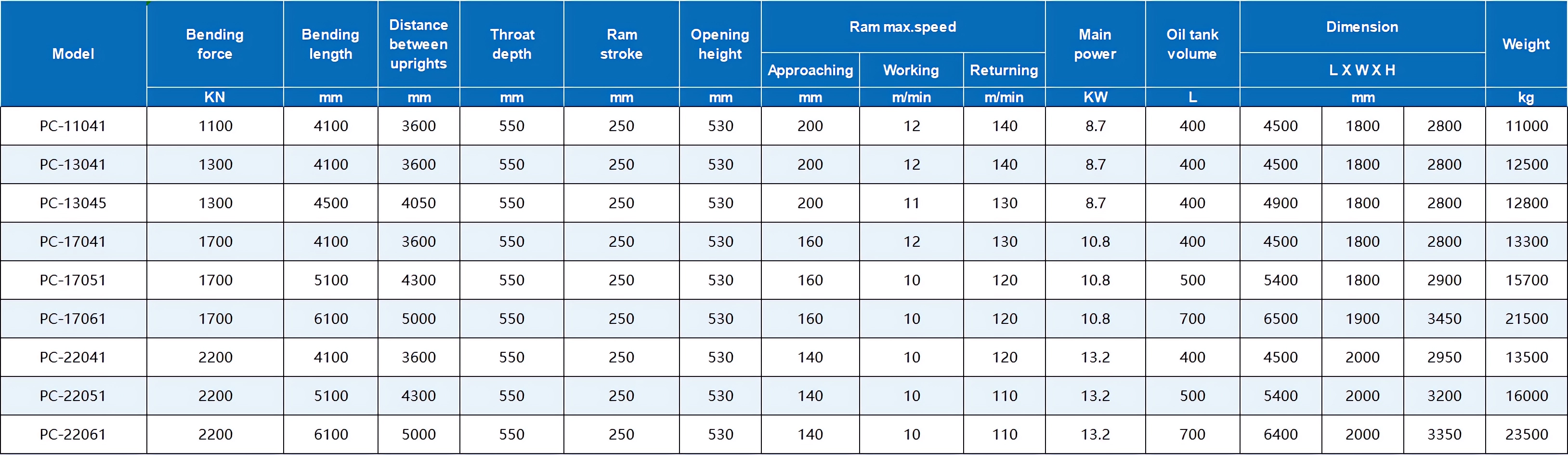

TECHNICAL SPECIFICATIONS