Three major process difficulties in high-power laser cutting machines

With unparalleled advantages such as large cutting width, fast cutting speed, and the ability to cut thicker plates, high-power laser cutting machines have been widely recognized by the market. However, because high-power laser cutting technology is still in the initial stage of popularization, some operators are not very proficient in high-power laser cutting skills.

Through long-term testing and research, Chuangheng has summarized a series of solutions to poor high-power laser cutting, hoping to help people who are confused.

If you find that the cutting effect is poor, you should first check the following reasons:

1. All lenses in the laser head are clean and free of contamination;

2. The water temperature in the water tank is normal and there is no condensation on the laser;

3. The cutting gas has excellent purity, smooth gas path and no air leakage.

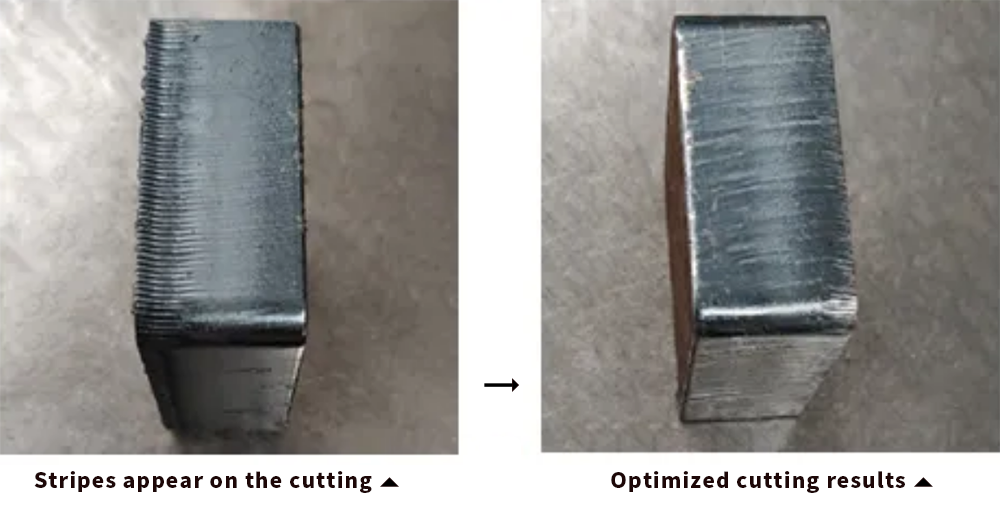

Question 1: Cutting strips

Possible Causes:

1. The nozzle selection is incorrect and the nozzle is too large;

2. The air pressure is set incorrectly, and the air pressure is set too high, resulting in overburning and streaks;

3. The cutting speed is wrong. Cutting speed that is too slow or too fast can also cause sufficient overburning.

Solution:

1. Replace the nozzle, and replace the nozzle with a smaller diameter. For example, for 16mm carbon steel bright surface cutting, you can choose high-speed nozzle D1.4; for 20mm carbon steel bright surface, you can choose high-speed nozzle D1.6;

2. Reduce cutting air pressure and improve end face cutting quality;

3. Adjust the cutting speed and match the power and cutting speed appropriately to achieve the effect as shown on the right as shown below.

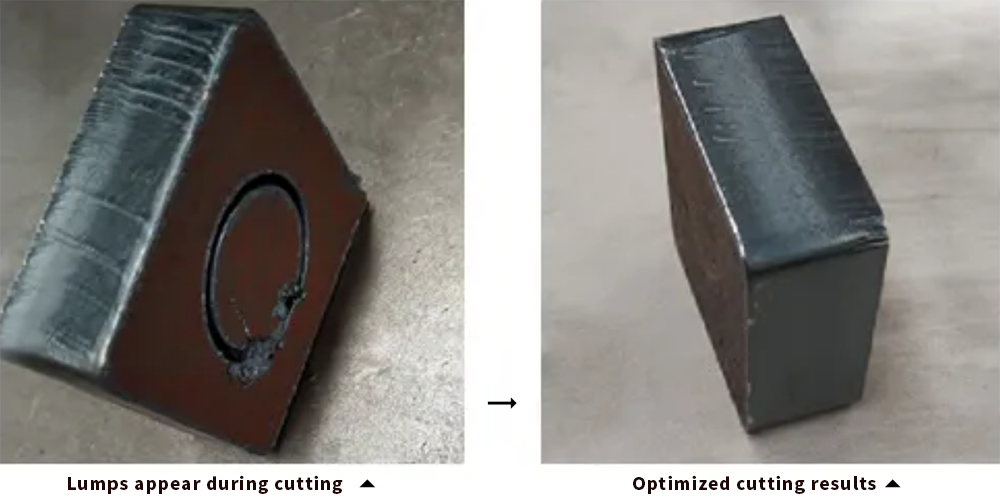

Question 2: There are lumps on the bottom

Possible Causes:

1. The nozzle is too small and the cutting focus does not match;

2. The air pressure is too small or too large, and the cutting speed is too fast;

3. The material of the plate is poor, the quality of the plate is not good, and it is difficult to remove the tumor residue with a small nozzle.

Solution:

1. Replace the large-diameter nozzle and adjust the positive focus to the appropriate position;

2. Increase or decrease the air pressure until the air flow is appropriate;

3. Choose good boards.

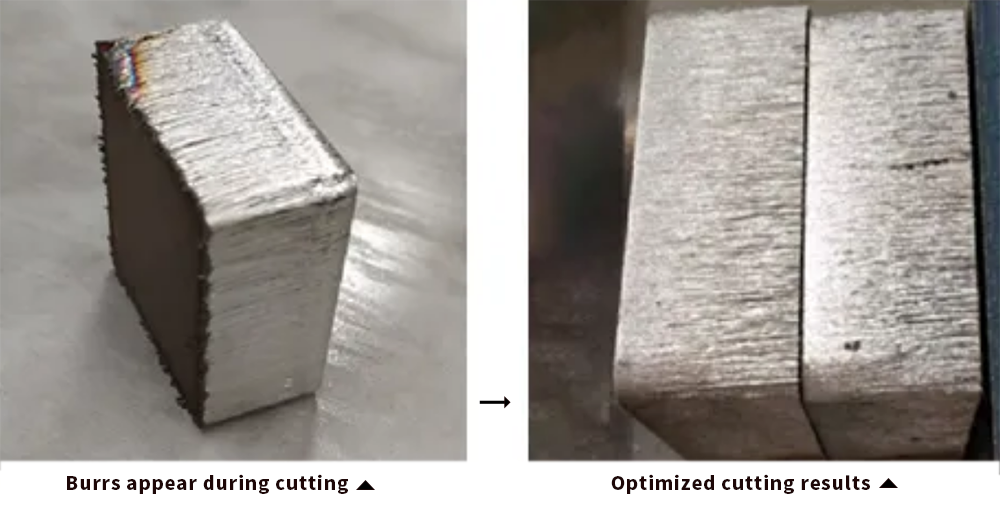

Problem 3: There are burrs on the bottom

Possible Causes:

1. The nozzle diameter is too small and cannot meet the processing requirements;

2. The negative defocus does not match, the negative defocus should be increased and adjusted to the appropriate position;

3. The air pressure is too low, resulting in burrs at the bottom and inability to fully cut.

Solution:

1. Use large-diameter nozzles to increase air flow;

2. Increase negative defocus to make the cutting section reach the bottom position;

3. Increasing the air pressure can reduce bottom burrs.