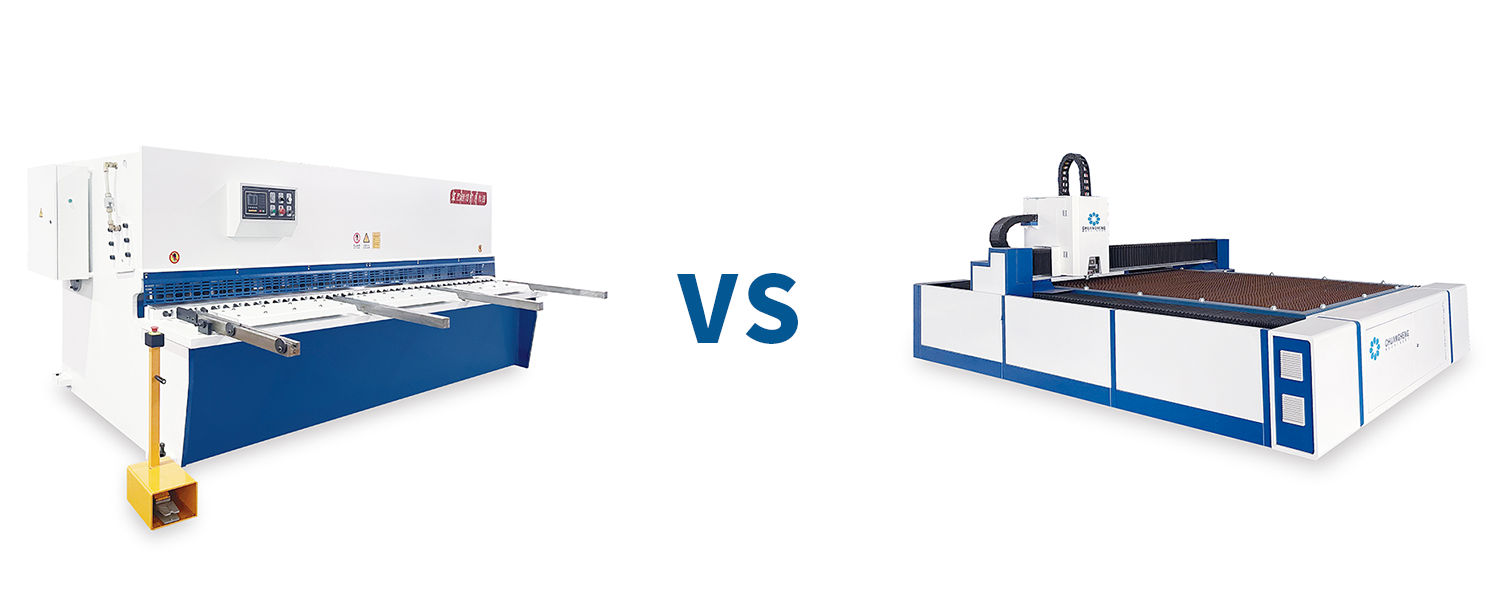

How to choose laser cutting machine or high-precision shearing machine?

Laser cutting machines and shearing machines each have their own disadvantages, so how can you choose to maximize your benefits?

First of all, you must choose according to the industry you are in. By comparison, laser cutting machines can cut out any special-shaped shape, save labor, and maximize cost utilization when processing thin plates of 1-3 mm. The shearing machine cuts straight strips faster than the laser cutting machine, and the processing range is between 0.2-30 mm. The thicker the plate, the faster it is. The efficiency of the thin plate is 5-10 times that of the laser cutting machine, and the precision is high and the stress is very small. High precision for subsequent bending. After the laser cutting machine is cut, there will be an error on the bending machine. The error is generally within 10 mm. Moreover, the cost of shearing machines is low. Only 3-5 shears can be worth one laser cutting machine. The use cost of laser cutting machines is high.

If you do not need to process special shapes, but only need to cut straight lines, a CNC shearing machine is recommended, and the thicker the plate, the faster it is processed; if you want to process special shapes or process thin plates between 1-3 mm, a laser cutting machine is recommended.