How to maintain stable performance of CNC PRESS BRAKE?

CNC press brake is a kind of mechanical equipment for sheet metal bending, and its accuracy and stability are crucial to product quality and production efficiency. In order to maintain the stable performance of CNC press brake, there are the following aspects to pay attention to.

The machine structure of the CNC press brake needs to have sufficient rigidity and stability to ensure smooth movement during processing. First of all, the machine bed should be made of high-strength, high-stiffness materials, and sufficient seismic reinforcement. Secondly, the joints of the various components of the machine tool need to be tightly calibrated and tightened to avoid vibration caused by loosening.

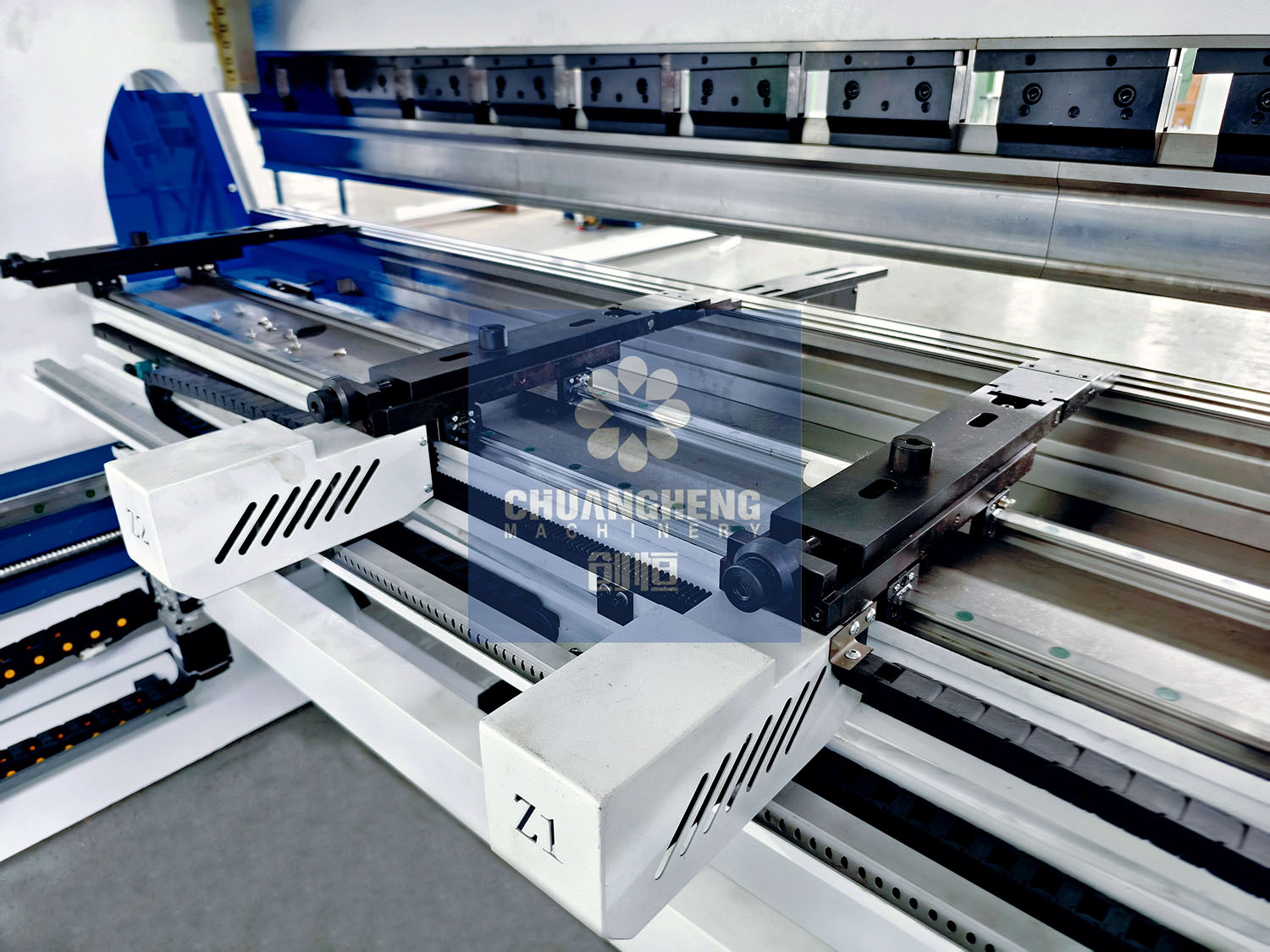

Second, the stability of the guide rail system

The guide rail system of the CNC press brake is the foundation of its motion accuracy and stability, so it needs to be kept well lubricated and maintained. In the process of use, regularly clean the dust and metal chips on the surface of the guide rail, and add oil or apply lubricating oil to reduce friction and improve the sliding performance of the guide rail system.

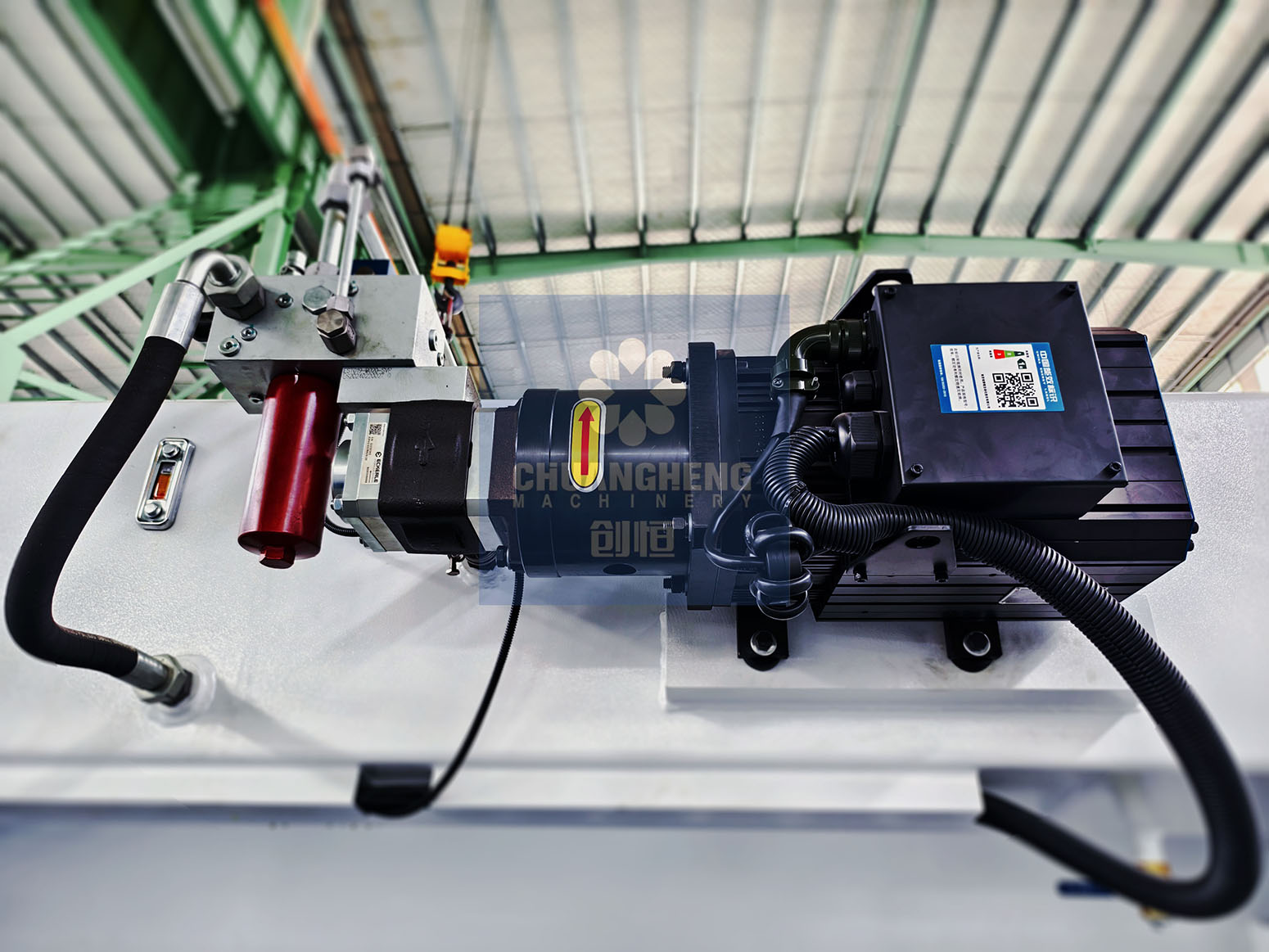

Third, Stability of servo motor and drive system

The servo motor and drive system of CNC bending machine are the key to control the machine movement, and their performance directly affects the machining accuracy and stability. In order to maintain its stable performance, it is necessary to check the working status of the servo motor and the drive regularly, replace the aging parts in time, and ensure that the communication between the motor and the drive is stable.

Fourth, the stability of the operating system

The operating system of CNC press brake controls the movements of the machine, so its stability has an important impact on the stability of the machine performance. In order to maintain the stability of the operating system, it is necessary to check and maintain the software and hardware regularly, update the operating system and related drivers, and repair bugs and faults in the system in a timely manner.

Fifth, the stability of the mold

The die of CNC press brake is an important tool for processing bending shapes, and its stability has an important impact on the accuracy and consistency of manufactured products. In order to maintain the stability of the mold, it is necessary to check and maintain the use of the mold regularly, repair or replace the damaged or deformed mold, and strictly control the processing technology and quality of the mold.

Sixth, Stability of process parameters

The stability of CNC press brake is also related to the setting and control of process parameters. Before bending, it is necessary to set parameters such as bending Angle and bending force reasonably according to the material and size of the workpiece, and adopt stable process control methods to ensure stability during processing.

Seventh, Accumulation of experience and technology

Maintaining the stability of the CNC press brake also requires the operator to have a wealth of experience and technology. Operators need to understand the working principle of CNC press brake and machine tool structure, familiar with the operating system and control methods, can adjust the process parameters in time according to the actual situation, discover and solve faults, and improve the operating efficiency and stability of the machine tool.

To sum up, in order to maintain the stable performance of CNC press brake, comprehensive considerations and measures need to be taken from the perspective of machine tool structure, guide rail system, servo motor and drive system, operating system, mold, process parameters and operators. Only in all aspects of reasonable configuration and effective maintenance, in order to ensure the long-term stable operation of CNC press brake and processing quality stability.