How to Choose a Press Brake Tooling?

1.Feeding Method

At present, there are two main feeding methods for the bending center. One is the suction cup feeding, which sucks the plate through a negative pressure pump. This requires the surface of the plate to be smooth and flat to ensure that the workpiece will not be dislocate during the feeding and rotation process.

The other is the pressing arm type feeding, which clamps the workpiece through the upper and lower pressing jaws. This method does not require the surface of the plate to be smooth and flat, and there are holes, surface indentations or a more complicated line of workpieces.As long as there is a place for loading The clip is fine, but the suction cup type cannot be used. The jaws of the pressing arm are generally small and can be adapted to smaller size workpieces.

The suction cup type equipment is very different from the pressure arm type in structure and feeding principle, and also has a big difference in price. If the suction cup type equipment can meet the demand,then the suction cup type bending center may be selected.Nice choice.

2 .Workpiece unfolding size

Compared with the equipment of 2.5 meters, the difference between the equipment of 1 meter and the equipment of 25 meters is still very large. The biggest advantage of the bending center is in mass production. When selecting the bending center, the best reference is the size of the workpiece that needs to be mass-produced.

3. Workpiece Thickness

When choosing a bending machine, customers need to determine whether it is a standard type ora customized type according to the thickness of the workpiece. The maximum bending thickness of the standard model is 2.0mm. Thickness up to 3.0mm.

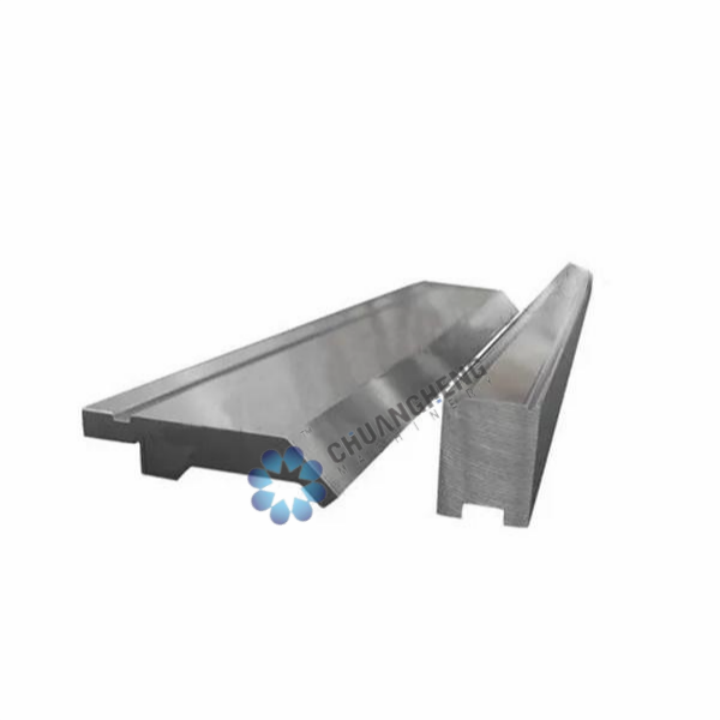

4. Bend Shape

Why do you need to customize the bending center that uses a universal mold? This is because when our lower folding knife folds up the last folded edge,the bevel of the pressing knife will collide with our workpiece. so that our last folded edge will be less than 90 degrees, In this case, it is necessary to customize the upper pressing knife according to the process of the workpiece, and appropriately cut off the colliding part, so that the bending can be realized.

There are many types of custom cutting tools, which are mainly analyzed according to the specific bending process of the workpiece. The cutting tools are independently developed and produced, so they can flexibly provide customized services for customers.